Surface analysis of a reference NGO FeSi electrical steel

ESIEE and IRT perform surface analyses on reference non-oriented grain (NGO) FeSi samples without laser processing

The ambition to influence the magnetic structure of a metal, its appearance and evolution during magnetization and demagnetization processes, requires first of all a clear understanding of the notion of magnetic structure on reference samples as a starting point. First metallographic and magnetic analyses were therefore carried out to characterize and visualize the distribution of crystalline grains and magnetic domains on the surface of an untreated reference FeSi NGO sample.

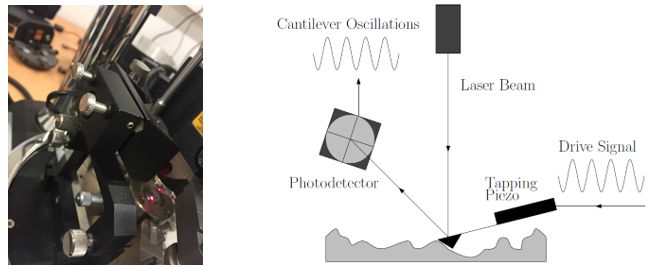

Figure 1: Image of a Magnetic Force Microscope and principle diagram of amplitude and/or phase contrast measurement.

The grain revelation technique is a chemical etching technique followed by optical microscopic observation. The principle consists in removing surface irregularities (scratches and oxide layers) until a very low roughness and an almost total disappearance of impurities, and therefore a very good surface finish. If necessary, this makes possible an observation of the metallographic structure after attack.

The magnetic domain observation technique uses the atomic force microscope in MFM mode (Magnetic Force Microscope) with soft and hard magnetic probes. The principle consists in oscillating a very fine magnetic tip at its resonance frequency above the surface to be analyzed and looking at the amplitude and phase variations of these oscillations caused by the magnetic interactions between the tip and the surface. The contrast obtained by the soft magnetic probe will be an image of the magnetic walls, i.e. the transition zones between one magnetic orientation and another. The contrast obtained by the hard-magnetic probe will be an image of the magnetic domains polarized in different directions. The dimensions of the MFM observation area may not exceed 120*120 micrometers2.

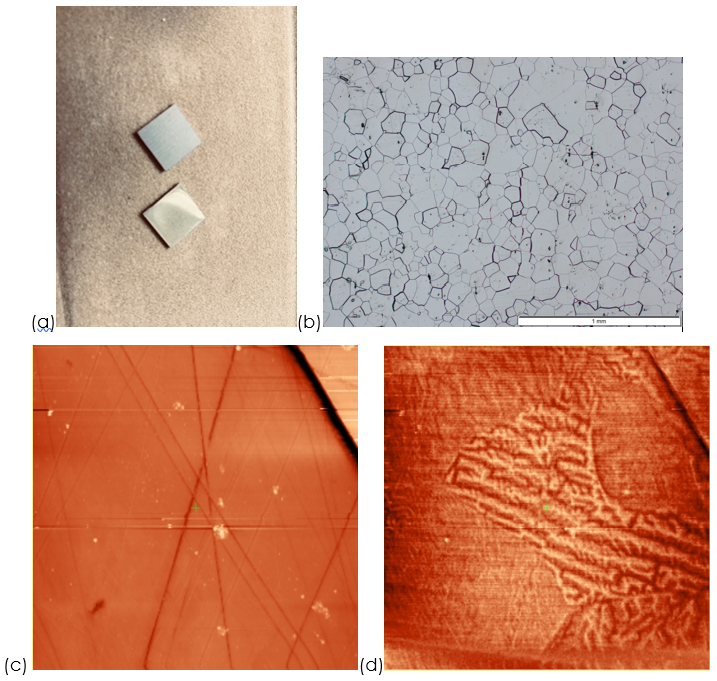

Figure 2: (a) Polished and unpolished samples (b) Revelation of grain joints in the metal (c) Surface topography by AFM revealing traces of polishing (d) Magnetic domains visualized by MFM with a hard-magnetic probe.

Non-oriented grain (NGO) electrical steels have generally an average grain diameter between 50 and 150 microns, confirmed in Figure 2.

Also, they are known for their small size of magnetic domains that favours the magnetization of the sheet under rotational field without huge power losses. In order to study the magnetic structure of NGO (NO-C5 without coating) standard sample from Jeumont, we used magnetic force microscopy imaging (MFM). The sample was polished before the experiment with silicon carbide paper (size of grain 0.1µm); the results are shown in the figures above (scan size 120µm). It is clear that we have small size of magnetic domains between 10µm and 20µm. The magnetic domains are distributed in different orientations and at the edge of every grain the configuration of the domain changes.