First campaign of uniform laser treatments on GO and NGO steels for magnetic measurements

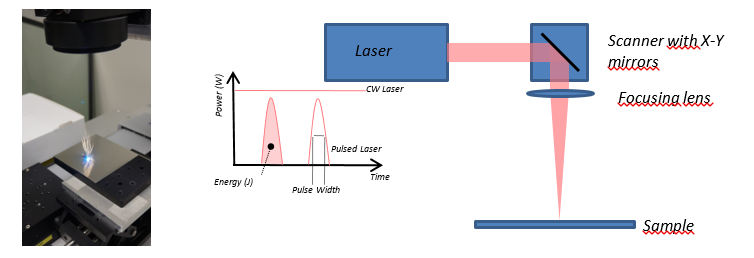

In the beginning of the project (M1 to M8) MULTITEL performed its first laser tests to select different laser parameters like pulse duration, power, scanning speed, or pattern (Figure 1).

Figure 1: Stages and laser machines - diagram.

ESIEE and UPJV then defined the experimental plans on the basis of a bibliography and the first behavioral models.

The three main LASERs currently considered for surface treatment tests are a continuous IR laser, a pulsed IR laser with pulse durations of a few nanoseconds, and an ultra-short pulse IR laser. Two effects are sought and must be studied both from the point of view of the laser experts and of material physicists. These two effects are i) stress induction by localized heating during laser irradiation and ii) laser ablation of material. The former is likely to influence the static magnetic permeability and the inclination of the static cycles, or to cause the appearance of closure domains that contribute to refining the domain structure. The latter is likely to influence dynamic iron losses by refining the magnetic structure, either by the appearance of magnetic poles and demagnetizing field or by the appearance of closure domains.

MULTITEL is now carrying out the laser treatment of various samples (FeSi NGO or FeSi GO in several sizes). Each shade meets a need of an end user and each of the sizes satisfies different constraints according to the magnetic characterizations to be performed. For all of these samples the laser treatment must be performed in a perfectly uniform manner on all of the two surfaces of the top and bottom of the sample. (Figure 2).

Figure 2: On the left, a picture of a sample treated or untreated by Laser. On the right, a magnetic testbed.

The objective is now to reduce the parameters set to a minimum. All parameters that lead to etching or irradiation profiles, which are incompatible with the requirements of flatness and roughness, are automatically eliminated. For other parameters set, magnetic properties will be considered. Once processed by MULTITEL, samples are sent to ESIEE Amiens to be characterized.