Back

Control of the magnetic domains refinement

The following work has been presented at the Materials Conference held in September 4-7, 2019, in Poznań, Poland.

A zero-field energy minimization principle to understand and control the magnetic domains refinement in GO SiFe – comparison between laser irradiation, scribing and ablation

O. Maloberti1,2, M. Nesser2, J. Fortin2, P. Dassonvalle1,3, J. Dupuy4, C. Pineau5, T. Nguyen6

1ESIEE Amiens, 14 quai de la Somme, 80080 Amiens, France. 2LTI Laboratory, Avenue des Facultés - Le Bailly 80 025 Amiens, France. 3MIS Laboratory, UPJV, 14 quai de la Somme, 80080 Amiens, France. 4MULTITEL, 2 rue Pierre et Marie Curie, 7000 Mons,Belgique. 5IRT-M2P, 4 rue Augustin Fresnel, 57070 Metz. 6CRM Group, Zone A4B, Technologiepark 922A, BE-9052 Zwijnaarde

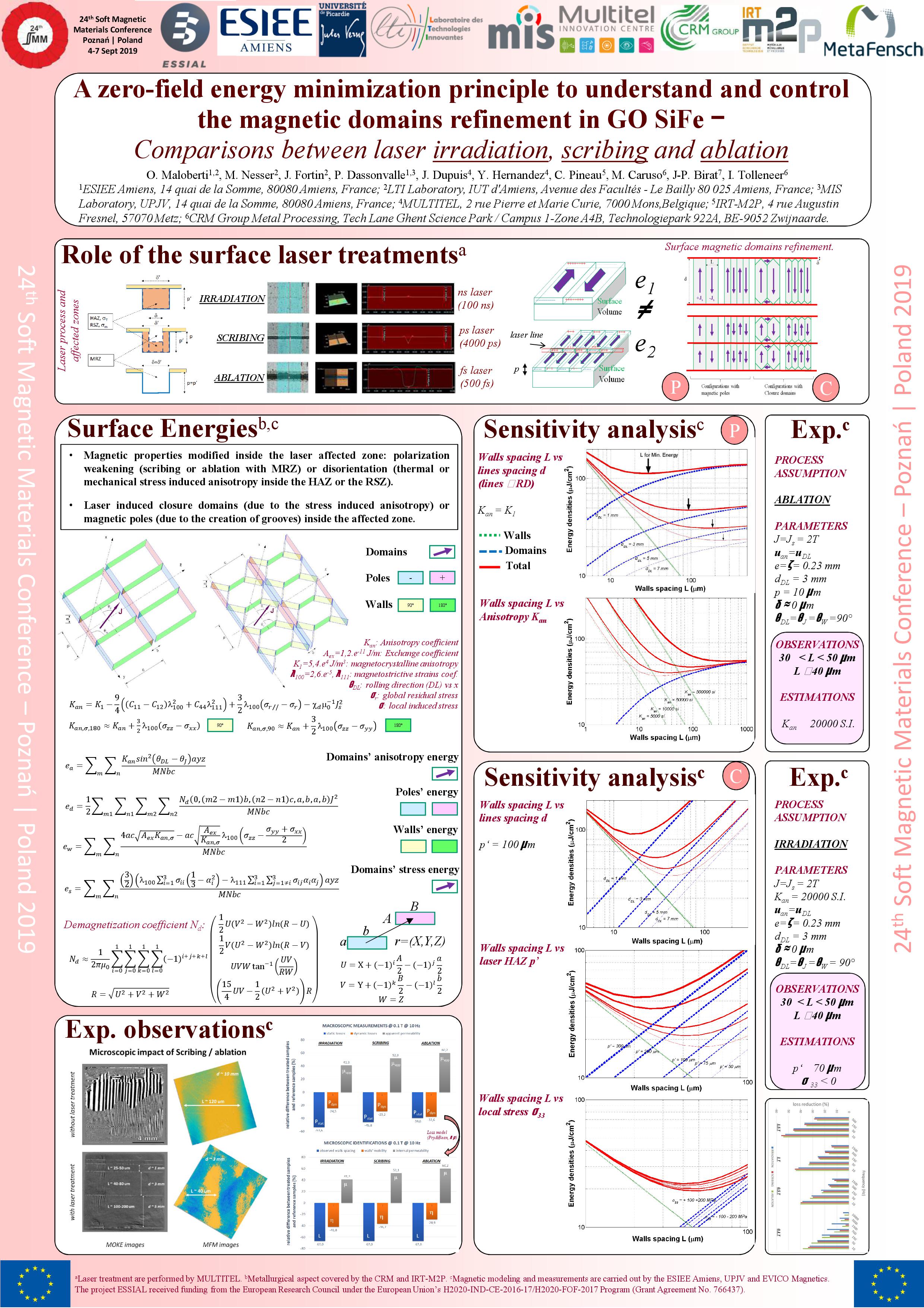

Surface treatments have appeared since the end of the 20th century to refine the magnetic structure of textured magnetic materials [1]. The theory called micro-magnetism can be used to describe the domain wall spacing but for very few domains and in a perfect crystal [2] or around small defects. In this paper, we look for the best laser mode and patterns to optimize the magnetic performances thanks to a pulsed laser irradiation, scribing or ablation process [3] (Fig. 1a). To do so, we investigate the impact of laser parameters onto the magnetic structure at zero external magnetic field. The domains wall spacing L will play the main role.

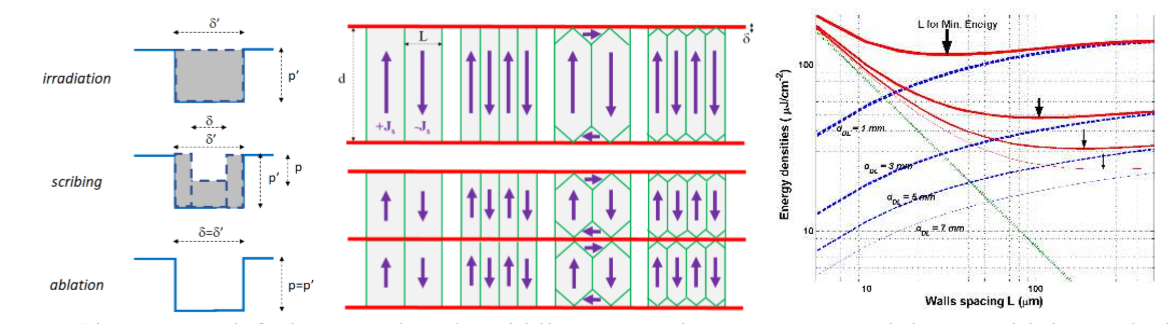

Figure 1: (a: left) laser modes, (b: middle): magnetic structures, (c: right): sensitivity analysis. In Fig. 1b, we consider parallel laser lines with a line spacing d and a magnetic or/and a heat affected zone (width δ and δ’ and depth p and p’) depending on the laser mode (irradiation (δ,p), scribing and ablation (δ’,p’)). Calculation of the magnetic, magneto-elastic and demagnetizing energies in walls, closure domains and main domains due to magnetic poles can be performed as a function of material and laser process parameters (line spacing d, width and depth (δ,p) or (δ’,p’), residual stress (s)). Then a sensitivity analysis (Fig. 1c) is carried out to analyze the impact of laser and magnetic parameters (L). This helps us choose the optimal laser parameters. Magnetic domains observation is carried out with the MFM and MOKE1 imaging techniques. The magnetic behavior is characterized with the SST2 frame.

References:

[1] T. Luchi, S. Yamaguchi, and T. Ichiyama, Journal Appl. Phys., vol. 53 (3), March 1982. [3] L. Landau, E. Lifshits, Reprinted Phys. Zeitsch. der Sow., vol. 8 (1935), pp. 153 – 169. [5] S. Patri et al., Journal of Material Science, vol. 31 (1996), pp. 1693 – 1702

1 MFM : Magnetic Force Microscopy / MOKE : Magneto-Optical Kerr Effect.

2 SST : Single Sheet Tester.

This research has received funding from the European Research Council under the H2020IND-CE-2016-17/H2020-FOF-2017 Program (Grant Agreement No. 766437)